What You Need to Know

In June 2023, the American Chemical Society released a new study around emissions monitoring and reconciling top-down and bottom-up inventories.

The study examined real emissions data captured over 11 months at five upstream oil & gas operators in 3 basins. The goal? Understand how to get to more accurate, measurement-informed emissions estimates given known issues with conventional bottom-up inventories.

The study found that using top-down and/or bottom-up methods alone is not reliable for emissions profiling. Continuous monitoring systems can be utilized to understand and reconcile deficiencies in top-down measurement and bottom-up inventory to create a holistic emissions profile of a facility.

- Top-down (i.e., aerial LiDAR and drone-based mass balance) snapshot measurements can differ drastically over time and significantly overestimate emissions. These discrepancies can be attributed to one-off events or operational changes—continuous monitoring solutions can help identify the cause.

- There are significant gaps in top-down vs. bottom-up inventory. Two operators had gaps of 96% and 94% when comparing the top-down measurement with a bottom-up inventory. Continuous monitoring helps bridge the gap with baseline emissions information over time.

- Bottom-up inventory can over- or under-estimate emissions, as proven when tracked against continuous monitoring measurements.

Using multi-scale measurement technologies to understand true emissions profiles is critical to meeting recent regulatory requirements in the Inflation Reduction Act, voluntary methane initiatives such as the Oil and Gas Methane Partnership 2.0, and corporate goals.

What This Means for You:

The study highlights the inconsistency and difficulty in understanding true emissions profiles using bottom-up inventory and top-down measurements alone. Intermittent measurements may capture short-lived, high-volume emission events and, therefore, can be higher than bottom-up inventories. Bottom-up inventories can either over- or under-estimate emissions profiles.

We dive deeper into the specifics of the study below, but there are two key takeaways to keep in mind:

- There are significant gaps in top-down vs. bottom-up inventories—top-down measurements were consistently higher than operator-provided bottom-up inventories.

- ·Continuous monitoring is essential to reconciling bottom-up and top-down inventories. The difference between bottom-up inventory and end-of-project top-down average was greater than 50% at the sites in the study where a continuous monitoring system (CMS) was not used.

CMS data should be used to create measurement-informed, site-level emission inventories that can be validated with top-down measurements to update conventional bottom-up inventories on oil and gas production sites.

How Project Canary Can Help

Project Canary is the leader in emissions data management. Our hardware and software portfolio best positions operators to measure, understand, and act on emissions events. Our SENSE dashboard visualizes and analyzes multi-scale measurement data, and Project Canary’s Carbon Portal allows for comparison to bottom-up calculations. The software ingests and displays parametric monitoring data to help further investigate emissions profiles and events. Project Canary leverages these tools to support operators in generating robust measurement-informed inventories.

See our industry-leading results from third-party testing (METEC, ADED 2023).

Unlike other continuous monitoring systems, Project Canary’s quantification model can account for buoyant plume rise by using an advanced algorithm – providing you with the granular data you need to reduce emissions.

With all this in mind, let’s dive a little deeper into the study and unpack what, specifically, the American Chemical Society has to say about the value of continuous emissions monitoring.

Go Deeper

Study Overview

Government policies and corporate strategies aimed at reducing methane emissions from the oil and gas sector require more accurate, measurement-informed emissions estimates. Conventional bottom-up inventories poorly capture temporal variability (changes over time) and the heavy-tailed nature of methane emissions.

- Bottom-up inventory methods have been shown to underestimate total emissions across multiple basins. Bottom-up inventories often represent month- or year-long averages and hence do not capture complex emission characteristics like temporal variability, nor do they account for differences in operational practices between operators. Certain emission sources may also be unaccounted for.

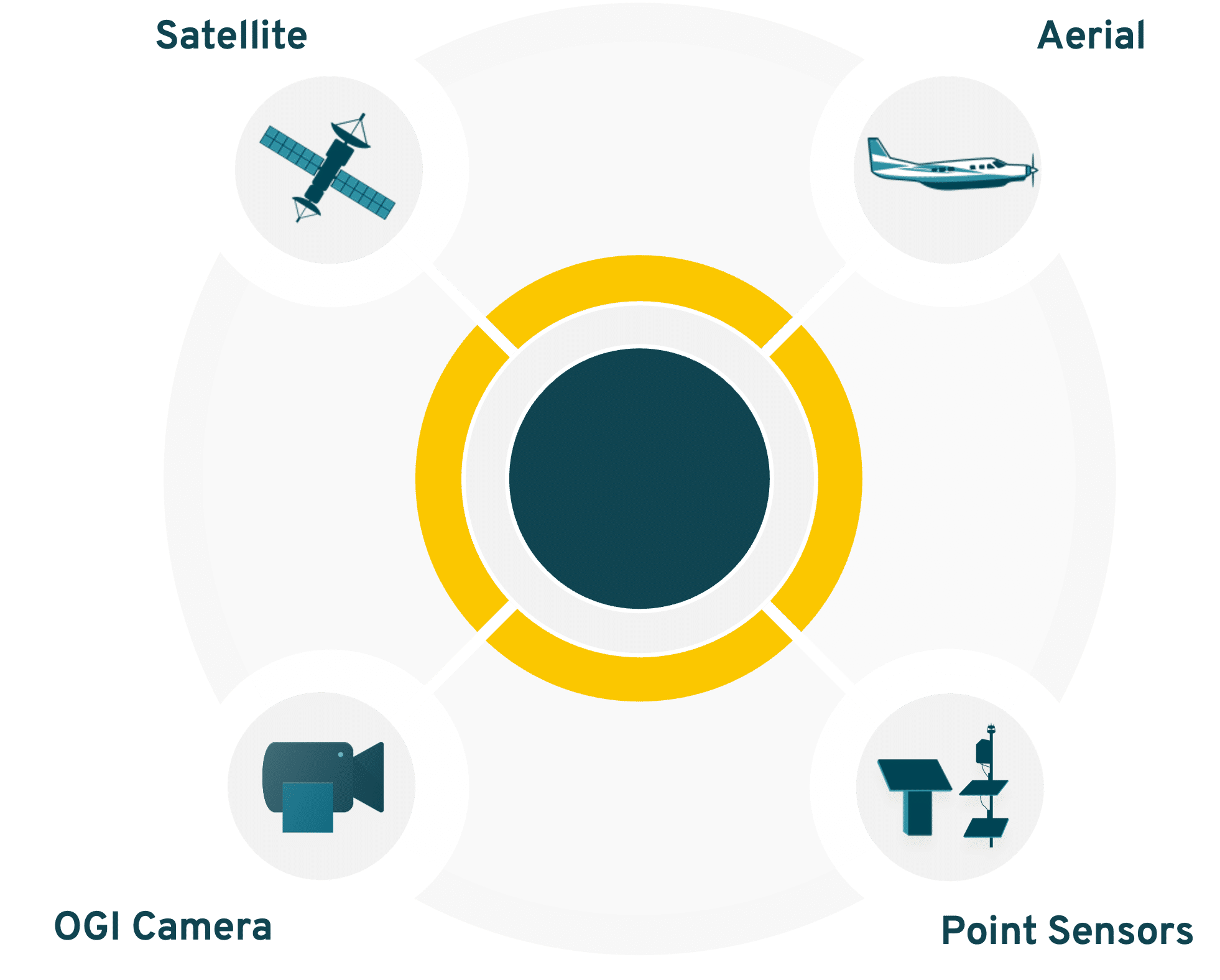

- Top-down snapshots (taken infrequently) are poorly suited for characterizing highly variable emissions at the site level, as any given measurement may or may not capture a short-lived emission event. These include satellite, aerial, and drone overflights. Quarterly and semiannual measurements result in systematic underestimation of total annual emissions.

Since continuous monitoring systems (CMS) provide measurements in near real-time, they are a promising avenue for complementing top-down measurement technologies.

To validate this hypothesis, this quantification, measurement, verification and reporting (QMRV) study looked at five upstream oil & gas operators in 3 basins: Marcellus, Haynesville, and Permian. It compared monitoring against operator-provided bottom-up inventories over an 11-month period.

Table 1: Measurement schedule of the QMRV project for enrolled sites at each basin.

| Basin | Enrolled Sites | Baseline Measurement | Enhanced Monitoring | End-of-Project Measurement |

| Basin A | 8 | Summer 2021 | Fall 2021 – Winter 2022 | Spring 2022 |

| Basin B | 5 | Summer 2021 | Fall 2021 – Spring 2022 | Spring 2022 |

| Basin C | 26 (20 used in analysis) |

Summer 2021 | Fall 2021 – Spring 2022 | Spring 2022 |

Intermittent monitoring:

- Two intermittent measurement technologies for both baseline and end of period:

- Drone-based mass balance technology provided by SeekOps Inc. (“SeekOps”)

- Aerial LiDAR plume identification system provided by Bridger Photonics, Inc. (“Bridger”)

- Some technologies were excluded from the final analysis: OGI was excluded because it is poorly suited for capturing total site-level emissions, and Satellite was excluded because of its high detection threshold (100 kg/h (38).

Enhanced monitoring period:

- Continuous monitoring system during the 6-month enhanced monitoring phase

- Though not revealed in the study, the CMS used was Project Canary’s Canary X and SENSE Premium software.

- Weekly audio, visual, and olfactory (AVO) inspections and monthly leak detection and repair (LDAR) surveys using either OGI cameras or Bridger measurements throughout the 6-month measurement period.

Bottom-up inventories were prepared according to GHGRP1 regulations and supplemented with additional emission sources not required by the GHGRP or known to be under-reported by the current GHGRP emission factors (e.g., methane slip in compressor engines, produced water tank emissions, vessel blowdowns, compressor blowdowns, and pressure relief valves).

Key Conclusions

1) Intermittent Monitoring Results Vary from Beginning to End of Period

There was significant variability in end-of-period measurements vs. those captured at start.

Emissions Rate at Beginning vs. End

Based on the average of Bridger and Seeker data, reported in standard cubic feet per hour (scfh).

| Baseline | End-of-Project | Baseline/End-of-Project Ratio | |

| Basin A | 1011 scfh | 387 scfh | 2.6x |

| Basin B | 387 scfh | 223 scfh | 2.1x |

| Basin C | 440 scfh | 150 scfh | 2.9x |

Overall, emission measurements were lower during the end-of-project phase than those during the baseline. These decreases could be due to temporal variability (the snapshot nature of the measurement) or to emission reduction practices implemented by the operators during the enhanced monitoring phase, which included monthly LDAR inspections.

2) Significant Gaps in Top-Down Measurement vs. Bottom-Up Inventory

The study showed that top-down measurements were consistently higher than operator-provided bottom-up inventory on the operator level.

Average SeekOps measurement to inventory ratio between baseline and end-of-project:

| Baseline Measurement vs. Inventory | End-of-Project Measurement vs. Inventory | |

| Basin A | 3.1x | 3.8x |

| Basin B | 1.7x | 3.2x |

| Basin C | 147.8x | 42.7x |

Average Bridger measurement to inventory ratio between baseline and end-of-project:

| Baseline Measurement vs. Inventory | End-of-Project Measurement vs. Inventory | |

| Basin A | 4.8x | 4.3x |

| Basin B | 1.3x | 4.2x |

| Basin C | 208.0x | 30.0x |

These variabilities could be due to (1) the snapshot nature of top-down measurements, meaning that Bridger and SeekOps happened to observe larger than average emissions during the measurement time or (2) generally underestimated bottom-up inventories.

Disentangling potential root causes requires high-frequency measurements to characterize intermittent emission events, as this will give an indication of whether a top-down measurement observed unusually large emissions for a given site.

3. Using Continuous Monitoring is Essential to Reconcile Bottom-Up and Tops-Down

In the two case studies discussed, the difference between bottom-up inventory and end-of-project top-down average was greater than 50% at each site when a CMS was not used.

Operator 1 Case Study

Operator 1 had a gap of 96% between operator-supplied, bottom-up inventory (20.5 scfh) and end-of-project top-down average (508 scfh). Continuous monitoring throughout the 6-month period was 60 scfh, much closer to the bottom-up inventory estimate.

Investigation into the data revealed there was a one-off tank emissions event captured by a flyover, resulting in the high top-down average of 508 scfh. CMS helped identify this by comparing it to trends over time.

By normalizing for one-off events throughout the monitoring period, CMS captures a more accurate baseline that helps bridge the gap to bottom-up inventory. For this operator, bottom-up inventory is likely to be underestimated since CMS measurement is roughly 3x higher than estimates.

Operator 2 Case Study

Operator 2 had a gap of 94% between bottom-up inventory (43.4 scfh) and end-of-project top-down average (726 scfh). The study used CMS to understand the temporal variability of emissions profile over time, examining data by equipment group.

There was an operator-reported GPU swap in the middle of the monitoring period that caused the overall emissions profile to increase (several 2 MMBtu/h GPUs were replaced with 1 MMBtu/h GPUs). CMS captured emissions timing and change in real-time.

Data on a month-by-month basis showed a spike in CMS data after February when the swap happened. Bottom-up inventory was over-estimating prior and under-estimating after the swap. The top-down estimate only captured the emissions profile after the swap.